Before any component of a Jaguar is shaped, milled, cast or pressed, it will have passed through hundreds of hours of optimisation, using highly advanced virtual engineering tools. Advanced Computational Fluid Dynamics (CFD) and Computer Aided Engineering (CAE) software can simulate hundreds of scenarios, much more time-efficiently and accurately than real-world trial and error. This helps us to create far more reliable solutions, while shaving months off development schedules.

Take our new-generation Ingenium engines for example, which went through the equivalent of two million kilometres of testing during their five-year development – much of which was done virtually.

“We think of design validation as a pyramid,” says Daniel Buckley, Ingenium Programme Manager. “The base is all the accrued knowledge within the organisation from previous projects and other sources. This powers the design options that our engineers develop. Working virtually using CAE, you can then iterate these design solutions more quickly and efficiently to find the best solutions for real-world validation testing at the pyramid’s peak. With Ingenium we used this new approach using significantly more CAE, rig and component level testing and this allowed us to iterate towards an optimised and reliable final production design much more quickly than previous projects."

CAE can simulate every scenario that a vehicle’s chassis and suspension are likely to go through during their life – including virtual crash tests, and extreme everyday scenarios such as object strikes, kerb impacts and pothole braking. A vehicle’s aerodynamic profile can be honed in a virtual CFD wind tunnel to minimise drag for better fuel economy and lower emissions, as well as improved engine and brake cooling, and more efficient in-car ventilation and climate control.

Virtual analysis lets vehicles be comprehensively tested and optimised early in the design and development process, without the delays and expense of manufacturing and re-manufacturing physical real-world parts. It also helps reduce the environmental impact of car production, typically saving 1.2 million kilometres of test-driving and 290 tonnes of CO2 during production of a Jaguar.

Although virtual engineering is a powerful tool, there’s no substitute for physical testing in a laboratory environment as the ultimate proof of concept for reliability and durability. We have doubled the size of our structural test facilities in recent years, with a R361m investment to further enhance our state-of-the-art labs.

New transmission designs go through a continuous 12-week rig test, simulating a 10-year 240,000 kilometre cycle that includes town driving, high-speed highway driving and track driving. This is repeated six times for different engine and transmission variants, meaning that every new gearbox is tested for 72 weeks and 1.45 million kilometres – the equivalent of driving to the moon and back. There are also shift cycle tests that put the clutch through a gruelling series of high-speed shifts, and steady-state tests where the transmission is run at high levels of torque for long periods.

Our engines have their own comprehensive suite of static rig and dynamometer tests, with the new generation of Ingenium engines having gone through 72,000 hours of durability testing – equivalent to eight years of real-world tests – before they hit the road for two million kilometres of final validation testing.

Jaguar F-PACE Engine Specifications

The Combined Road Environmental Test – known as the ‘squeak and rattle’ test – is used to optimise vehicles for noise, vibration and harshness, with high-quality equipment recording interior sounds as the car is jolted, jiggled and jostled on four powerful pistons. Tests are replicated with just the driver, then a full load of passengers and luggage to ensure optimum performance in all conditions.

Individual components can be tested in the Environmental Robotic Durability Cell, which uses four robots, which can be used to test everything from seatbelt activation and release, door opening and closing, and key turns. Vehicle noise, vibration and harshness qualities are also refined in advanced anechoic sound chambers.

Climate Chambers replicate the world’s toughest weather conditions, freezing cars to -40ºC in hurricane-strength winds, or replicating the sort of +50ºC temperatures and solar loads of up to 1,200W/m2 that you’d expect in the Sahara desert – all without vehicles ever having to leave the UK. Water-tightness is proven with monsoon soak tests, drizzle tests that last up to 16 hours, and freeze tests.

Physical laboratory testing even extends to interior features such as the rotary JaguarDrive Selector, which was subject to every abuse imaginable during its development. “A bottle of cola is a tough test, as the sugar turns to treacle in hot climates,” says Julian Jones, User Controls Manager. “Sand can also be bad if it gets in the DriveSelector’s gears.” Each test takes a month to run, with the DriveSelector having to cycle 60,000 times without fault.

When a finished Jaguar design makes it to the production line, the quality checks remain just as obsessive.

In the Engine Manufacturing Centre (EMC), all the elements of our Ingenium engines are tested repeatedly through the production and build – a process called ‘no faults forward’. “We set ourselves the challenge of making the EMC the best engine plant in the world, in terms of quality” says Daniel Buckley, Ingenium Programme Manager. “For example if we find a problem, the engine doesn’t go into a separate off-line rework process. Instead, it is taken off the production line, stripped down to the required level and then reintroduced to the line at an earlier station. This ensures that an engine never bypasses the extensive quality systems and controls of the production line to maintain the highest level of quality."

Major components are stamped with a unique QR barcode to trace their build date and location, and are measured by laser to ensure accuracy to three microns, or 0.003mm – 6 percent of the thickness of a human hair. Random samples are also tested by hand, in a controlled 20ºC laboratory environment for total precision of the carefully calibrated tools.

JLR Engine Manufacturing Centre, Wolverhampton

Before any engines leave the EMC, they are tested on specially designed rigs. First, a ‘cold test’, in which components are rotated for 72 seconds without igniting the engine. Then the engine is brought to life with a ‘hot test’, where it is ignited and goes through a 240-second cycle, at speeds up to 3,000rpm.

Finally, engines are taken off the line at random and go through a full dynamometer test, in which they are run flat-out at 240km/h for 300 hours or 72,400 kilometres.

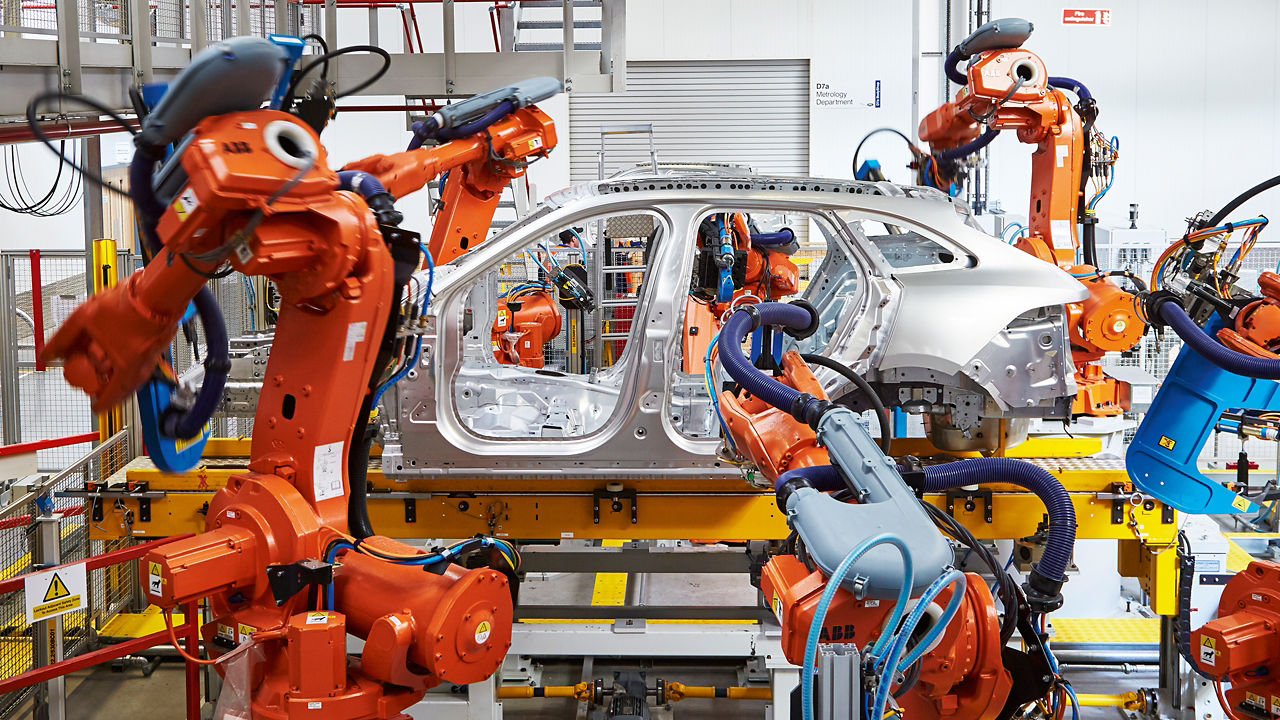

At our vehicle production lines in Solihull and Castle Bromwich, freshly pressed aluminium panels are examined under a light box for any blemishes and faults. As the chassis is assembled, cutting-edge lasers and cameras carry out a 168-point quality check, while panel gaps are checked with hand-held gauges. “Some car makers aim for +/-3mm tolerance, but our aim is +/-0.5mm,” says Arthur Richards, Production Supervisor at Castle Bromwich. “It’s what gives a Jaguar its look and feel of quality craftsmanship.”

At the end of the assembly process, the chassis is treated with a clear varnish and examined under UV light. Any minor blemishes are marked, and addressed by hand.

Painting the chassis is a 24-hour process. First, it goes through a series of 13 cleaning, conditioning and rinsing tanks, as well as an advanced electro-coating process, to ensure a reliable adhesion between the aluminium and paint. The chassis is cleaned with emu feather brushes. “Emu feathers can be easily charged with static electricity, which makes them great for picking up dust,” says Nigel Williams, Paint Area Manager. “And because the feathers have a large surface area, they provide a lot of coverage. We wouldn’t use them if they didn’t work so well, because – to be honest – they are very expensive.”

The chassis is then sprayed with three coats of paint – a primer, a base coat, and a final clear coat, which improves durability for UV rays, and corrosive tree sap and bird droppings, before being baked at 170ºC for one hour.

On the trim and finish lines – as the chassis passes through 92 stations, with around 1,000 parts added to the car – great care is taken to eliminate the risk of damage to the painted chassis. Covers protect exterior panels, while trim specialists wear special clothing and boots with eyelets and buttons that cannot scratch the paintwork.

At the end of the production line, every car goes through a final set of checks – including being drenched with 6,000 litres of water in just four minutes to ensure water-tight seals, before the car is run on a rolling road at high speed in every gear, and has a 20-minute electronic diagnostic test.

Even as a Jaguar is being delivered to its customer, the checks continue. All the road transporters, trains and ships used in the process have been checked using virtual CAD analysis to simulate loading, while cars undergo a 90-check process that can be repeated up to 30 times during the transport process.

“Jaguar has always stood for design and engineering excellence,” says Arthur Richards. “It’s our job to achieve a strict design specification on the final product, and we’re serious about our discipline. We’re building luxury cars – we want to exceed our customers’ expectations for quality and reliability.”

MORE STORIES